Laboratory of

Diffractometry

Diffractometry

Laboratory of

Diffractometry

Diffractometry

Department of Catalysis on Metals

Institute of Physical Chemistry, Polish Academy of Sciences

![]()

Laboratory of X-Ray Powder Diffraction and Spectrometry has been created in 1994 in the Institute of Physical Chemistry (Warsaw,Poland) within the Department of Catalysis on Metals. It was based on the established in 1960-ties by the Department of Catalysis on Metals, X-Ray Laboratory headed by dr A.Janko and later by prof.J.Pielaszek. The laboratory undertakes projects involving widely understood phase analysis and Rietveld refinement of structural data based on laboratory and synchrotron powder diffraction patterns as well as dynamical and kinetic studies in situ in variable, controlled atmosphere and programmed temperature (from R.T.upto~600 oC).

The laboratory specializes also in the analysis of the state of organization of quasi-amorphous materials. Our long time experience and expertise was focused on the studies of such materials using wide angle X-Ray Powder Diffraction as well as Radial Distribution Function method (RDF). We have contributed to the method developing the most accurate to date convolutional method of normalization of the scattering pattern (Kaszkur, J.Appl.Crystall.,23 ,180-185 (1990)). Quality of the method was later confirmed by Cumbrera et al.,J.Appl.Cryst.28, 408-415 (1995) in the paper entirely devoted to our method. We have also developed many numerical techniques to study highly dispersed solids (transition metals) deposited on supports (SiO2,Al 2O3). These techniques include reliable background estimation in the XRD pattern, data smoothing procedures and quantitative analysis oriented towards in situ studies. Recently we develop a series of analytic tools allowing insight into the structure and dynamics of nanocrystalline metalic particles in a chemical reaction environment. These techniques are developed and verified on the basis of molecular simulations. They may detect degree of relaxation or reconstruction of the surface of metal nanoparticles exposed to chemical reagents. We can follow in situ surface violation of the crystal symmetry, nanocrystal reshaping during the reaction or anisotropic reconstruction. This opens up new avenues of insight into the elementary chemical reactions at the atomistic level. The new techniques are developed within the research group "Dynamics of nanocrystal structure induced by surface chemistry" established in 2008. The "proof of concept" papers as well as several studies are listed as methodology papers below.

Head of the Laboratory

![]()

equipment

equipment

-X-Ray Diffractometer D5000 (Siemens) equipped with Goebel optics (Cu Ka ) (for photo click here ),

-X-Ray Diffractometer Geigerflex (Rigaku-Denki) ( for photo click here ),

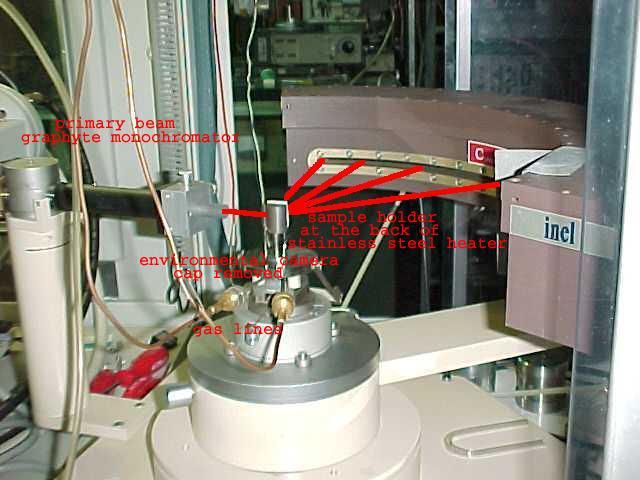

-Position Sensitive Detector CPS 120 (Inel), covering 120oarc, with channel separation ~0.03o (for photo click here ),

-Position Sensitive Detector type Brown 50M, covering ~10o arc, with position resolution <80ľm, set up also in scanning mode,

-Strip detector LynxEye (Bruker), allowing for quick parallel detection on 192 solid state strips and significant speed up of the overall pattern measurement (for photo click here ),

-range of our own design chemical reactors- X-ray cameras developed for in situ X-ray studies in a controlled atmosphere in flow of selected gases, mixtures or vapors of particular pressure at selected programmed temperature ( for photo click here ).

-two Mass Spectrometers (1-200 amu, from Hiden and AMETEC) adapted to probe gases in- or outgoing from the XRD camera.

- computer controlled gas supply system with two mass flow controllers from MKS,

-Energy Dispersive X-Ray Fluorescence Spectrometer (MiniPal4 from PANanalytical) for elemental analysis of elements with Z>10 (starting from Na) (for photo click here ),

- A range of software packages for powder diffraction data reduction and analysis, purchased as well as developed in the laboratory, complementing our equipment.

Experiments can be fully programmed using bash scripts of O.S. Linux. The scripts include commands for temperature controllers, mass flow controllers, mass spectrometers vacuum pumps, diffractometers etc. - all working in a local network of the Laboratory. The scripts enable detailed programming of the experiment along a precisely designed physico-chemical scenario. This approach simplify achieving full repeatability of the experiments.

IN-SITU REACTOR

IN-SITU REACTOR

(TO USE WITH PSD, SCHEMATIC VIEW)

Technical details of the measurement

For analysis we usually require 50-200mg of powdered sample that can be either deposited (smeared over and/or pressed) on a surface of a rectangular piece of porous glass (~10x20 mm) for in situ studies, or pressed into sample holder in the form of a shallow ditch in the surface of glass or plastic. To avoid texture problems occurring on pressing the sample we sometimes use flat surface MYLAR envelopes spread over thin frame or Capton self-adhesive tape. The envelope can be loosely filled with the material under study which, for the materials of low absorption, provides means to use transmission geometry of X-ray Diffraction measurement. In the latter case the amount of the material available has to be increased to 1-2 g (depending on its density).

![]()

Among the programs routinely used in the laboratory there are packages for data and structure visualization, powder diffraction pattern synthesis (LAZY-PULVERIX, MERCURY) and Rietveld refinement (GSAS, FULLPROF) or phase analysis (Match, HighScore Plus). For handling long series of data files collected in dynamical in situ measurements we have developed software basing on the concept of the list of data (program INEL). Most of the developed routines can then be applied to survey the desired feature of all marked data patterns from the active list. Such approach enables e.g. extraction of a one-peak characteristics evolution during thermal treatment and/or a phase transition. Thermal expansion coefficient, peakwidth and intensity evolution can thus be reliably calculated and displayed. The program, written in Borland Pascal 7.0 using a user friendly platform of Turbo Vision, is currently rewritten into free pascal Lazarus platform (OS Linux). The program uses data formats as provided by Inel's Diffractinel software as well as ASCII free format.

Development of our software included

theoretical simulations of small metallic clusters (graphic

interface, energy relaxation, Molecular Dynamics (MD), Monte Carlo

(MC), powder diffraction simulation etc.). The modeling encompasses a

long range Sutton-Chen potential for metals and Embedded Atom Method.

Most of the simulation tools is included into program CLUSTER written

as 32 bit Delphi application (currently rewritten to 64 bit Lazarus)

and handling a large number of metal atoms

limited only by the size of physical memory. For typical fcc metal it

enables tracking down consequences of structural details on the

diffraction pattern and radial distribution function (RDF) of

nanocrystals. The topics which may be addressed this way include

thermal expansion and melting of nanocrystals (employing MD), surface

segregation in bimetallic nanocrystals (employing MC techniques),

surface contraction of metal nanocrystals, impact of surface

interactions on the geometry (powder diffraction), surface

reconstruction, cluster agglomeration and many other. A specific

experiment-oriented approach enables averaging of RDF and diffraction

pattern over long MD run as well as estimation of thermal expansion

from the shifting position of a main diffraction peak.

Recently

the laboratory addressing the general strategy of software investment

made a move towards Linux environment and attempts to base most of

experimental software on open source projects. Program CLUSTER is

being developed in two versions: strictly computational in Linux

(Free Pascal) command line mode, and in Linux X-windows environment

based on Lazarus. Data acquisition software for INEL

CPS120 position sensitive detector is being developed in network

based form under Linux GPIB open source project. Also 5 temperature

controllers and the environmental camera gas feeding system control

have been arranged under Linux with networked, written in c programs.

The development allows for easy experiment control via the extensive

scripting environment.

The Laboratory has been also involved in EXAFS studies of catalysts using synchrotron radiation (LURE, Daresbury, DESY-Hasylab ) as well as in construction of a laboratory EXAFS spectrometer. The experience gathered profited in the development of EXAFS analysis and simulation program (XAS) written with Turbo Vision platform of Borland Pascal 7.0. The package includes most of a widely used data reduction and normalization routines, FourierTransform, one coordination sphere extraction and fitting, extraction of amplitudes and phases from experiment as well as the use and fitting of simulated data from the worldwide acknowledged FEFF program, with which the package is well integrated.

Older home-based software includes simulation of the stereographic projections of a defined structure along any chosen axis-the program designed to aid single crystal orientation procedure.

![]()

Wojciech Juszczyk PhD Eng. |

|

wjuszczyk@ichf.edu.pl |

Zbigniew Kaszkur PhD, D.Sc. |

head of the laboratory |

zbig@ichf.edu.pl |

Dmitry Lisovytskiy PhD Eng. |

|

dl@ichf.edu.pl |

Boguslaw Mierzwa PhD |

|

godan@ichf.edu.pl |

Ewa Trzetrzewiǹska M.Sc |

|

trzetrze@ichf.edu.pl |

Ewa Tym |

|

ewat@ichf.edu.pl |

The general subject of interest of the Laboratory is:

Structure of highly dispersed solids (nanocrystals) and its dynamics during physical processes and chemical reaction.

During last years the Laboratory carried research financially supported by the following grants:

![]()

Jerzy Pielaszek, professor, PhD, D.Sc.

M.Sc., 1965- Department of Physics, University of Warsaw, Poland

Ph.D., 1972- Institute of Physical Chemistry PAS, Warsaw, Poland

D.Sc., 1996- Department of Physics, Warsaw Technical University, Poland

Professor, 2004 - Institute of Physical Chemistry PAS, Warsaw,

Poland

Professional affiliations:

Polish Crystallographic Association

Polish Chemical Society

1972 - Commissariat à L´Enérgie Atomique, Fontenay-aux-Roses, France

1974 - University College of Wales, Aberystwyth, Walia, UK

1981-1983 - Nortwestern University, Evanston, USA

2001, 2002, 2003, 2005 - Université Henri Poincaré, Nancy, France

Research areas:

Selected papers ( since 2002):

Pielaszek J., "X-Ray Diffraction from Nanostructured Materials" chapter in: Nanocrystalline Metals and Oxides, Selected Properties and Application, Eds. P. Knauth, J. Schoonman, Kluwer Academic Publishers, 2002.

Juszczyk W., Karpiński Z., Łomot D. and Pielaszek J., Transformation of Pd/SiO2 into palladium silicide during reduction at 450 and 500°C. J. Catal., 220, 299-308 (2003).

Laberty Robert Ch., Fontaine M.L., Mounis T., Mierzwa B., Lisovytskiy D., Pielaszek J., “X-ray diffraction studies of perovskite or derived perovskite phase formation”. Solid State Ionics, 176, 1213–1223 (2005);

Pielaszek J.,

Mierzwa B., Medjahdi G.,Mareche J.F., Puricelli S., Celzard A.,

Furdin G. ”Molybdenum carbide catalyst formation from precursors

deposited on active carbons; XRD studies”. Appl. Catal. A-Gen., 296,

232-237 (2005).

Kopeć M., Lisovytskiy D., Marzantowicz M., Dygas J.R., Krok F., Kaszkur Z., Pielaszek J., „X-ray diffraction and impedance spectroscopy studies of lithium manganeze oxide spinel”, J.Power Sources, 159, 412-419 (2006).

Total

number of publications: 104.

M.Sc - Warsaw University, Faculty of Physics, in "Mathematical Methods of Physics", 1977.

Ph.D - Institute of Physical Chemistry Polish Academy of Science, in Solid State Physics, 1987,

D.Sc - Warsaw Technical University, Faculty of Physics, in Solid State Physics, 2008.

Field of research

Powder Difraction, Atomistic Simulations, Diffraction on nanocrystals, Radial Distribution Function analysis, Interpretation of surface phenomena on metal nanocrystals via diffraction.

Professional affiliations:

Research areas:

Structural analysis of highly dispersed and amorphous solids,

Dynamical and in situ powder diffraction of highly dispersed metals,

Molecular simulations of metal nanoclusters and bimetallic nanosystems,

Diffraction full profile and peak shape analysis,

Radial Distribution Function analysis,

Interpretation of surface phenomena on metal nanocrystals via diffraction,

Transport phenomena in the nanoworld.

Selected methodology papers:

Selected other papers from 2009:

Link to Zbigniew Kaszkur home page

![]()

E-mail x-ray@ichf.edu.pl

Institute of Physical Chemistry PAS

Warszawa 01-224, ul. Kasprzaka 44/52

Telephone : (22)3433284 or 3433417

Fax : (22)3423450

![]()

Last modified: 03/30/2015 16:30

by Zbigniew Kaszkur - zbig@ichf.edu.pl

![]()